When it comes to investing in a trailer, whether it’s a custom flat top trailer, custom trailer, or any other type of custom made trailers, the quality of construction is paramount. The longevity, safety, and functionality of your trailer depend largely on the craftsmanship and materials used during the building process. For this reason, carefully assessing the quality of work from trailer builders near me is crucial to ensure that your investment is worthwhile.

Key Indicators of High-Quality Custom Trailer Construction

Durability and Material Quality

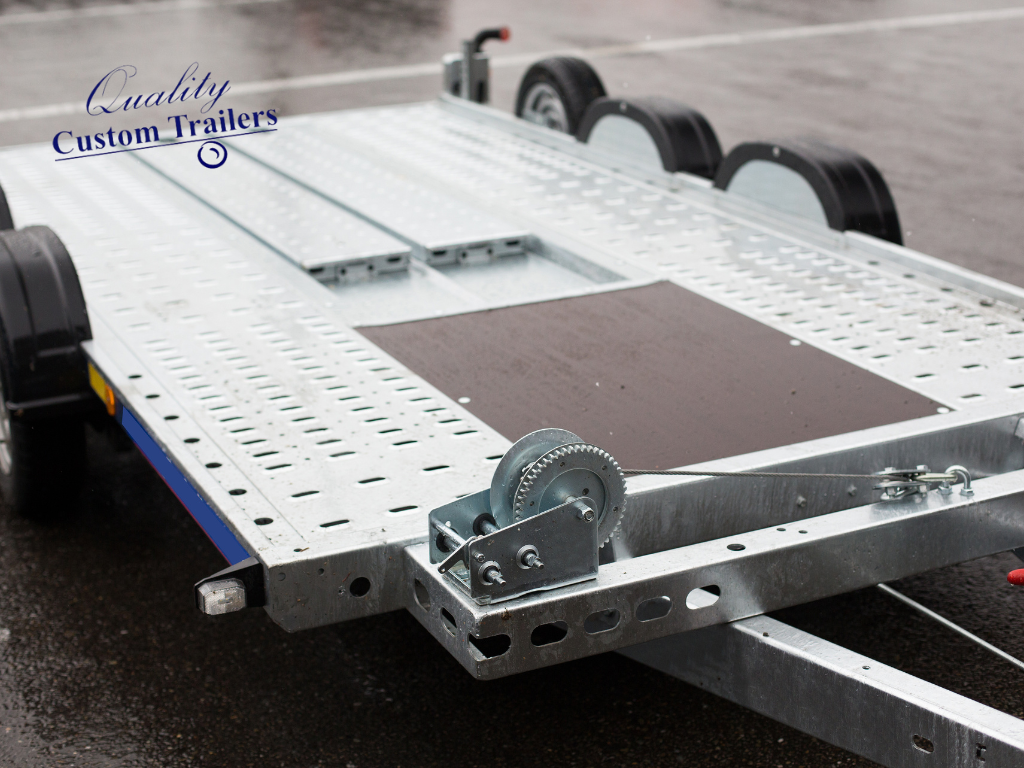

One of the primary indicators of high-quality construction in custom trailers is the durability of the materials used. Whether you’re looking at a custom flat top trailer or another type of custom made trailer, the materials chosen by the builder will greatly influence the trailer’s ability to withstand wear and tear over time. High-quality materials like galvanized steel or aluminum are preferred for their strength and resistance to corrosion, ensuring that the trailer remains functional and safe for years.

Craftsmanship and Attention to Detail

Craftsmanship is another critical factor in the quality of a custom trailer. Even the best materials can be compromised by poor workmanship. When assessing trailer builders, look for evidence of meticulous attention to detail in their previous work. This includes checking welds for consistency and strength, ensuring that all joints and connections are secure, and verifying that the finish is smooth and even.

Inspecting the Build Quality of Custom Flat Top Trailers

Structural Integrity and Load-Bearing Capacity

For custom flat top trailers, structural integrity is particularly important as these trailers are often used to carry heavy loads. Ensuring that the frame and load-bearing components are robust and well-constructed is essential to avoid issues like bending, warping, or even failure under load. When inspecting a custom flat top trailer, pay close attention to the thickness and quality of the frame materials, as well as the design of the load-bearing elements.

Finish Quality and Resistance to Corrosion

The finish of a custom trailer not only contributes to its appearance but also plays a crucial role in protecting it from the elements. For example, a high-quality paint job or powder coating can prevent rust and corrosion, extending the life of the trailer. When evaluating the build quality of a custom flat top trailer, inspect the finish closely. Look for any signs of uneven application, peeling, or areas where the coating is thin or missing.

Evaluating Customization Options for Your Trailer

Available Custom Features and Their Quality

One of the main advantages of choosing custom made trailers is the ability to tailor the trailer to your exact needs. This might include features like additional storage compartments, reinforced flooring, or specialized tie-down systems. When considering trailer builders near you, it’s important to assess not only the range of customization options they offer but also the quality of these features.

Flexibility in Design to Meet Specific Needs

Flexibility is a key benefit of working with a custom trailer builder. A good builder should be willing to work with you to design a trailer that meets your unique requirements, whether that means adjusting dimensions, incorporating specific features, or adapting the design for a particular use case. When evaluating builders, consider their willingness to accommodate your requests and their ability to suggest practical solutions.

Understanding the Materials Used in Custom Made Trailers

Types of Materials Commonly Used in Trailer Construction

When considering custom made trailers, one of the most important factors to understand is the materials used in their construction. The choice of materials can significantly impact the trailer’s durability, weight, cost, and suitability for different tasks.

- Steel: Steel is a popular material for trailer construction due to its strength and durability. It is particularly well-suited for heavy-duty trailers, such as custom flat top trailers, where load-bearing capacity is critical. However, steel is also heavier than other materials, which can increase the overall weight of the trailer and reduce fuel efficiency.

- Aluminum: Aluminum is another common material, valued for its lighter weight compared to steel. This makes it an excellent choice for trailers where weight is a consideration, such as for easier towing and better fuel efficiency. Aluminum also has the advantage of being resistant to rust and corrosion, making it ideal for trailers exposed to harsh environments. However, it is generally more expensive than steel.

- Wood: While less common for the entire structure, wood is often used for decking or flooring in trailers. It provides a non-slip surface and can be easily replaced if damaged. However, wood requires regular maintenance to prevent rot and decay, especially in trailers exposed to moisture.

- Composite Materials: Some custom trailers may use composite materials, which combine the benefits of various substances, such as fiberglass, plastics, and metals. Composites can offer a good balance of strength, weight, and durability but can be more expensive and may require specialized repair techniques.

Pros and Cons of Different Materials

Each material used in trailer construction comes with its own set of advantages and disadvantages:

- Steel:

- Pros: Strong, durable, ideal for heavy loads.

- Cons: Heavy, prone to rust without proper maintenance.

- Aluminum:

- Pros: Lightweight, rust-resistant, good for fuel efficiency.

- Cons: More expensive, may not be as strong as steel for heavy-duty applications.

- Wood:

- Pros: Provides a non-slip surface, easily replaceable.

- Cons: Requires regular maintenance, susceptible to rot and moisture damage.

- Composite Materials:

- Pros: Lightweight, strong, resistant to various environmental factors.

- Cons: Can be costly, may require specialized repairs.

The Importance of Welding and Joint Quality in Custom Trailers

How to Inspect Welding Quality

Welding quality is a critical factor in the structural integrity of any custom trailer. The strength and durability of the trailer depend heavily on how well the different components are joined together. Poor welding can lead to weak joints, which may fail under stress, posing serious safety risks.

When inspecting welding quality, look for:

- Consistent Weld Beads: Good welds should have a uniform appearance with consistent width and height. There should be no gaps, cracks, or undercuts in the weld bead.

- Smooth Surface: A high-quality weld should have a smooth, even surface without excessive spatter or rough edges. This indicates that the weld was performed correctly and is less likely to have internal defects.

- No Visible Defects: Check for any signs of porosity (tiny holes), cracking, or incomplete fusion in the weld. These defects can compromise the strength of the joint.

Why Joint Strength is Crucial for Trailer Longevity

The strength of the joints in a custom trailer is crucial for its longevity and safe operation. Joints are the points where different parts of the trailer frame and body are connected, and they bear significant stress, especially when the trailer is loaded.

- Stress Distribution: Strong joints ensure that stress is evenly distributed across the trailer, reducing the likelihood of cracks or breaks. This is particularly important in custom flat top trailers, which may carry heavy and uneven loads.

- Durability: Well-constructed joints contribute to the overall durability of the trailer, allowing it to withstand the rigors of regular use and harsh environmental conditions.

- Safety: Weak joints can lead to structural failures, which can be dangerous on the road. Ensuring that your custom trailer has strong, well-crafted joints is essential for your safety and that of others.

Verifying the Builder’s Experience and Expertise

How Long Have They Been Building Custom Trailers?

Experience matters when it comes to building custom trailers. The longer a builder has been in the business, the more likely they are to have refined their craft and developed a reputation for quality. When choosing trailer builders near you, it’s important to consider how long they have been operating and their track record in producing custom flat top trailers or other custom made trailers.

- Experience: Ask the builder about their years of experience in the industry and how many custom trailers they have built. A well-established builder is more likely to have encountered and solved a variety of challenges, leading to better outcomes for your project.

- Specialization: Some builders specialize in certain types of trailers, such as custom flat top trailers or heavy-duty trailers. If your needs are specific, it’s worth finding a builder with expertise in that particular area.

Checking Their Portfolio and Previous Work

A builder’s portfolio is a valuable resource for assessing their skills and the quality of their work. Reviewing previous projects gives you insight into their capabilities and whether they can meet your expectations.

- Portfolio: Ask to see a portfolio of completed projects, including photos and descriptions of the custom trailers they have built. Pay attention to the level of detail, craftsmanship, and overall finish of each trailer.

- References: Request references from previous clients and follow up with them to ask about their experiences working with the builder. Positive feedback from past customers is a strong indicator of a reliable and skilled trailer builder.

Reading and Interpreting Customer Reviews

What to Look for in Online Reviews

Online reviews can provide valuable insights into the reputation and reliability of trailer builders near you. However, it’s important to approach reviews critically, looking for specific information that reflects the builder’s quality of work and customer service.

- Quality of Work: Look for reviews that mention the quality of the trailers, including durability, finish, and functionality. Positive comments about these aspects suggest that the builder delivers on their promises.

- Customer Service: Reviews that highlight the builder’s communication, responsiveness, and willingness to address issues are important indicators of good customer service. A builder who is easy to work with and attentive to client needs is more likely to produce a satisfactory outcome.

- Timeliness: Pay attention to comments about whether the builder completed the project on time. Delays can be frustrating, especially if they are not communicated effectively.

How to Spot Red Flags and Consistent Praise

While no builder is perfect, consistent patterns in reviews can help you identify red flags or confirm a builder’s reliability.

- Red Flags: Repeated complaints about issues like poor workmanship, missed deadlines, or unresponsive communication should be taken seriously. These patterns may indicate ongoing problems that could affect your project.

- Consistent Praise: On the other hand, consistent praise for a builder’s craftsmanship, attention to detail, and customer service is a strong endorsement. Builders with a high number of positive reviews are more likely to meet or exceed your expectations.